Production processes

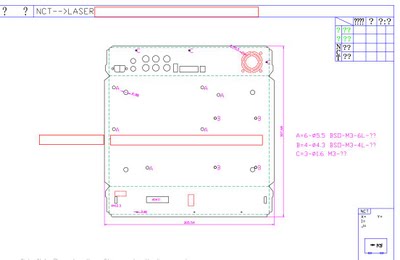

NC Programming

Our CAD/CAM staff would deal with the NC programming, passing the files to the NCT. Above all, the materials needed would be under careful observation

Materials evaluation

If in your case which would be made of special materials, our Materials would be purchasing the raw material, then ask NCT to start the production.

Computerized numerical punching

We will make sure the surface quality of the product after being through the pre-operation.

Processing

The operation of tapping, riveting.

NC Press Brake

Work on the product to bend and shaped.

Welding processing

This process permanently joining two or more metal parts, by melting both materials. Spot welding and seam welding are two very popular methods used for sheet metal parts.

Semi-finished goods inspection

We examine the semi-finished goods according to the Spec. instructed by clients for avoiding defective.

Electroplating - Print

After all detail examined, we start electroplating, printing on needed.

Final inspection

QC staff do the final check & test with strong attention during the last production process.